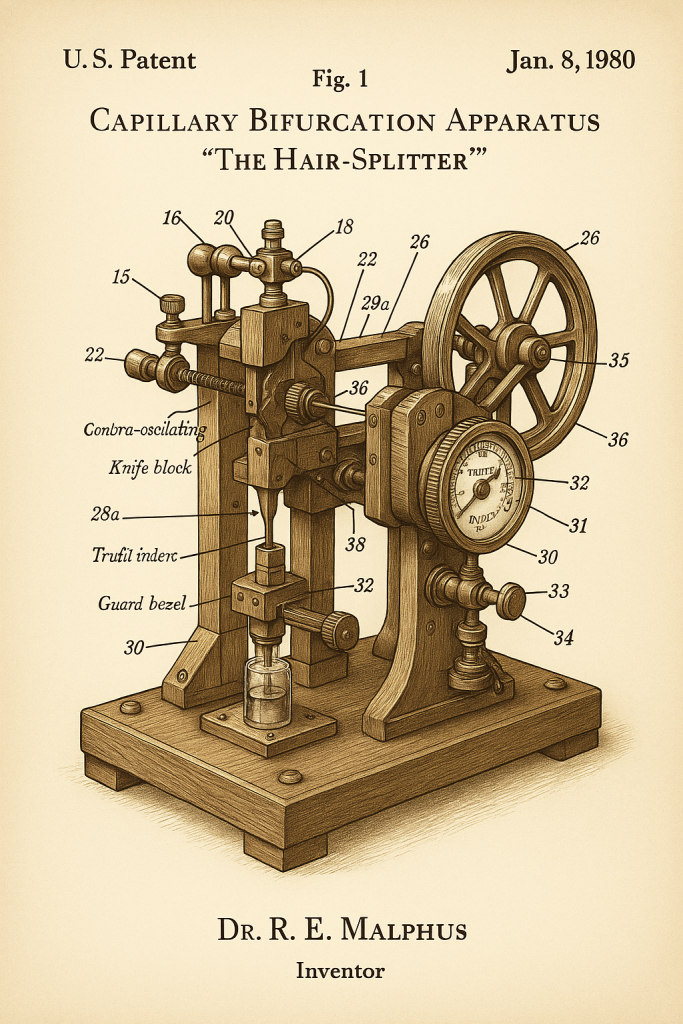

Original patent for The Capillary Bifurcation Apparatus

Us Patent — Capillary Bifurcation Apparatus (“the Hair‑splitter”) By Dr. R. Malphus

UNITED STATES PATENT

Patent No.: US X1,843,221

Title: Capillary Bifurcation Apparatus (aka “The Hair‑Splitter”)

Inventor: Dr. R. Malphus, Davenport, Iowa

Filed: October 31, 1897

Issued: April 1, 1898

ABSTRACT

A manually or belt‑driven apparatus for the mechanical subdivision of a single human hair into progressively finer filaments for purposes of demonstration, disputation, and the advancement of pedantry. The device employs a micrometer carriage, a harmonic flywheel, and a contra‑oscillating knife assembly which assures that no practical outcome is achieved.

FIELD OF THE INVENTION

This invention relates to benchtop mechanisms and, more particularly, to devices configured to manipulate exceedingly small, uncooperative subjects in order to resolve arguments that do not materially matter.

BACKGROUND

Disputants have long undertaken the figurative act of “splitting hairs.” Prior approaches—heated debate, raised voices, and pointed index fingers—lack repeatability. A need exists for a repeatable, calibrated, wood‑and‑brass machine that literalizes the gesture while consuming an afternoon.

SUMMARY

The apparatus secures a hair within a tapered collet and advances it by micrometer to a vibrating guillotine knife. A harmonic flywheel tuned by an eccentric governor produces a sympathetic oscillation, ensuring division into two (or, optionally, four) filaments of equal futility. Output is collected in a Result Vial for archival.

BRIEF DESCRIPTION OF THE DRAWINGS

Fig. 1. Perspective view of complete apparatus on walnut base.

Fig. 2. Exploded view showing frame, flywheel, governor, knife block, and micrometer carriage.

Fig. 3. Micrometer carriage with tapered collet and alignment comb.

Fig. 4. Contra‑oscillating knife block, spring pack, and cam follower.

Fig. 5. Harmonic flywheel and belt drive with adjustable pulley.

Fig. 6. Governor assembly (“Destiny Regulator”).

Fig. 7. Output chute and Result Vial with cork.

Fig. 8. Calibration gauge (“Truth Index”) and operator pointer.

DETAILED DESCRIPTION WITH REFERENCE NUMERALS

10 Base, walnut, 14″ × 8″ × 1.25″.

12 Upright frame, white oak trestle with brass cross‑tie.

14 Main shaft, 6 mm tool steel, polished.

16 Flywheel, turned brass Ø90 mm with four spokes.

18 Belt, leather, 6 mm wide, hand‑stitched.

20 Adjustable pulley with knurled set screw.

22 Eccentric cam, brass, provides ±1.0 mm throw.

24 Cam follower with hardened pin and phosphor‑bronze bush.

26 Spring pack, three tempered leaf springs, selectable.

28 Knife block, contra‑oscillating, matched 12° included angle.

30 Guard bezel, nickel silver, removeable for cleaning.

32 Micrometer carriage, travel 0–25 mm, 0.01 mm gradations.

34 Collet, tapered, knurled nut, accepts 30–120 µm filament.

36 Alignment comb, boxwood, 0.1 mm teeth.

38 Truth Index dial (arbitrary scale 0–11).

40 Destiny Regulator (centrifugal governor), twin brass balls Ø14 mm.

42 Output chute, blued steel, to 44 Result Vial (glass) with cork 46.

48 Hand crank with rosewood knob.

50 Foot treadle (optional) with linkage rod 52.

54 Leveling feet, neoprene pads under brass cones.

56 Name plate, engraved: Capillary Bifurcation Apparatus.

Operation: Rotation of crank 48 drives belt 18, spinning flywheel 16. Eccentric cam 22 actuates follower 24, reciprocating knife block 28 at frequencies governed by 40. Micrometer 32 advances the hair via collet 34 through comb 36 into the knife aperture; severed filaments exit via chute 42 to vial 44.

CLAIMS

- A benchtop apparatus comprising: a base (10); an upright frame (12); a rotatable main shaft (14) bearing a flywheel (16); an eccentric cam (22) coupled to a contra‑oscillating knife block (28); and a micrometer carriage (32) configured to advance a filament into the knife block, whereby the filament is mechanically subdivided without producing a utilitarian result.

- The apparatus of claim 1, wherein a centrifugal governor (40) modulates cam frequency to a range sufficient to suggest precision to any onlooker.

- The apparatus of claim 1, wherein the micrometer carriage (32) retains the filament within a tapered collet (34) and aligns the same by means of a boxwood comb (36).

- The apparatus of claim 1, wherein the knife block (28) comprises paired blades ground to a 12° included angle and mounted on a spring pack (26) to deliver an audible, authoritative click.

- The apparatus of claim 2, further comprising a dial indicator (38) scaled from zero to eleven, the scale being arbitrary yet persuasive.

- The apparatus of claim 1, wherein the base (10) is walnut and the frame (12) is white oak, the visible metallic components being brass with deliberate patina to convey erudition.

- A method of literalizing disputation comprising: securing a hair within the collet (34); advancing the hair by the micrometer (32); energizing the flywheel (16); and repeatedly splitting the hair until all parties forget the original point.

PREFERRED MATERIALS & FINISHES

- Wood: Black walnut base; white oak frame; boxwood comb; rosewood crank knob.

- Metal: C360 brass (flywheel, cam, hardware); O1 tool steel (knife edges, main shaft); phosphor bronze (bushings); blued mild steel (chute).

- Fasteners: Slotted brass wood screws; M4 cheese‑head machine screws; taper pins.

- Finishes: Shellac (1‑lb cut) + beeswax on wood; liver‑of‑sulfur patina on brass; light gun‑blue on steel; enamel‑filled engraving on name plate.

Indicative Dimensions (mm unless noted): Base 356×203×32; frame height 220; flywheel Ø90×12 thick; belt length 420; knife aperture 0.25 wide; collet bore 0.12 tapering to 0.03.

BILL OF MATERIALS (BOM)

- Walnut plank 14″×8″×1.25″ — 1 pc

- White oak stock ¾”×¾”×24″ — 1 pc

- Brass round bar Ø3/8″ — 24″

- Tool steel flat 1/8″×1″ — 12″ (blades)

- Phosphor bronze bushing Ø6 mm ID — 2 pcs

- Leather belt 6 mm×450 mm — 1 pc

- Glass vial w/ cork — 3 pcs

- Boxwood offcut (comb) — 1 pc

- Assorted brass screws, M4 machine screws, taper pins — as req.

WORKSHOP FABRICATION PLAN

Tools: Small wood lathe; metal lathe (optional); drill press; fret saw; files; chisels; taps/dies M4; calipers; burnisher; sharpening stones; buffing wheel.

A. Base & Frame

- Mill walnut base to final size; chamfer underside; install threaded inserts for 54.

- Cut oak uprights; half‑lap cross‑ties; glue and pin with 1/8″ brass dowels.

- Add brass cross‑tie plate with countersunk screws for rigidity.

B. Shafts & Motion 4. Turn main shaft 14 and flywheel hub; press fit and pin.

5. Cut and drill eccentric cam 22 with set screw; ream follower bushing.

6. Fabricate governor 40: two pivoting arms with brass balls on pins; link to flywheel hub.

C. Knife Block 7. Grind paired blades from O1 to 12° included; harden at 800°C; temper straw; hone to mirror.

8. Assemble spring pack 26 between knife carriers; test snap with feeler gauge.

9. Add guard bezel 30 with two knurled thumb screws.

D. Micrometer Carriage 10. Salvage or fabricate a 0–25 mm micrometer head; mount on dovetail slide.

11. Turn tapered collet 34 with split and knurled nut; drill to 0.12 mm pilot; polish.

12. Cut boxwood comb 36 on fret saw; sand to 0.1 mm teeth; wax.

E. Drive & Controls 13. Install leather belt 18 and pulley 20; add treadle 50 if desired.

14. Engrave name plate 56; enamel fill; screw to base.

F. Finish 15. Seal wood with shellac; buff wax; patinate brass; blue steel; oil bushings.

G. Calibration 16. Set governor to 4–6 Hz at moderate crank; align blades; test on nylon filament before hair trials.

OPERATION

- Insert a single hair into collet 34; snug gently.

- Advance micrometer until hair appears within guard 30.

- Crank 48; adjust 40 until the Truth Index 38 reads a satisfyingly ambiguous value.

- Collect fragments in 44; document results in a ledger of negligible insights.

MAINTENANCE

- Hone blades every 50 splits.

- Wax belt monthly.

- Re‑shellac seasonally.

SAFETY NOTICE

Not intended for practical application. Keep fingers, beards, and philosophical commitments clear of the knife aperture.

CATALOG BLURB (For the Malphus Broadsheet)

“HAIR‑SPLITTER, Model 1980.” For the gentleman scholar who refuses to leave well enough alone. Walnut and brass. Audible certainty with measurable irrelevance. Includes three Result Vials.

VISUAL PRODUCTION NOTES

- Plate A (Patent Sheet): Monochrome linework, stippled shadows, aging cream stock, bold header “United States Patent,” figures 1–8 with callouts.

- Plate B (Catalog Cut): Sepia engraving, title ribbon, price medallion, concise sales copy.

- Palette: Warm brass, oiled walnut, blued steel; crisp black ink for the patent plate.

- Type: Headers in a hard serif (Didone or Scotch), labels in small caps; numerals engraved style.

ALT VARIANTS (for future editions)

- Four‑Way Splitter: Crossed knife pair for quartering the filament.

- Auto‑Feed: Weighted escapement that draws hair at constant rate (claim dependency on 32).

- Optical Loupe: Fold‑out magnifier with 3× lens and theatrical importance.

PROMPT BLUEPRINT

U.S. patent plate of a wood‑and‑brass benchtop machine called “Capillary Bifurcation Apparatus (Hair‑Splitter)” by Dr. R. E. Malphus.

END OF SPECIFICATION